- Contact us

- Westatlantic Products

- Stainless Couplings and Restraint

- High-Pressure-Coupling

- Tapping Sleeves Flange

- Tapping Tees Thread

- Pipeline Repair Clamps

- Flange Leak Repair Clamps

- Split Barrel Repair Clamps

- Split Sleeve Boltable Clamps

- Drilling Saddles Stainless Steel

- Couplings Flange Adaptors DI-epoxy-coated - galvanized --"Lloyds approved"

- Grip Couplings

- Pipeline Expansion Joints

- Repair Clamps

- Pipe Stiffners HDPE PVC

- Marine Products

- Contact us

Split sleeve boltable repair

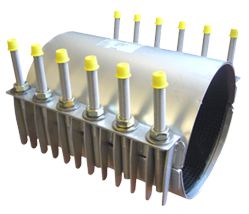

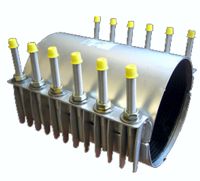

Pipe Repair Clamps - Split Bolted - High Pressure

High pressure pipe repair clamps

ANSI pressure classes 300, 400, 600, 900, 1200 and 1500.

Pipe remains In service during Installation

Split repair clamps WA-SBC repair units, bolt closed around leaks in a pipe section. WA-SBC high pressure leak repair clamps may be installed on oil, gas, steam, water and chemical pipelines.

Repair Clamp seals may be NBR or VITON or other seals compatible with the pipeline fluid and operating temperature.

Split Bolted Repair Clamp Install Video

Forged High Pressure Monolithic clamps cut sheet:

Split Pipe repair clamps-sample drawings

WA-SBC repair clamps are hydrostatically tested to 1.3 times the rated working pressure (as per ASME Section VIII Div.1 clause UG-99) All Clamps are equipped with a 1” NPT vent port.

Seals may be replaceable without special tools.

DESIGN STANDARDS AND SPECIFICATIONS

- ANSI Pressure classes 300-1500

- Design based on API 6H. Design calculation ASME Sec. VIII Div. I

- Body materials A516 Gr. 70, ASTM A105

- PTFE coated bolts and nuts, bolt material A193 Gr. B7 and nut material A194 Gr. 2H

- Standard coating yellow epoxy 100 microns

- Gaskets (H) NBR or Viton

- Weldable option is available with heat insulating gaskets

- Double row sealing is available on request

- Sacrificial anodes can be installed on the sleeves for long term cathodic protection

- Non-standard lengths are available on request

- Full MTC document will be supplied with the order

LEAK REPAIR CLAMP Material

- Material: ASTM A 516 Gr.70 / ASTM A 105

- Fasteners: ASTM-A-193-B7 & ASTM-A-194-2H

- Seal: Buna “N‟

- Paint: Epoxy Coating Yellow 100 Microns

- Vent Port + Plug: Yes Lifting Lug (8” & above)

- Hinge Assembly: (8” & above) Yes

- Design Temperature: 65ºC N.D.T.

- 100% RT Butt Weld - 100% U.T. of vent plug welds. (Fillet)

- 100% MPI of Hinge welds. (Fillet)

- Certification: EN 10204 3.1

- Design Calculation: ASME Sec. VIII Div. I

See: sample spec 600 class clamp:

WA-solid block pipe leak repair clamp: Bolt Closing

* WA solid clamp is a special product used in applications with small diameter pipes.

- * The clamp is made from a single metal block forging.

- * WA-Solid block leak repair clamps are custom made for customer defined conditions.

| Location | Size Range (Inch) | ANSI Class | ||

| Offshore / Onshore | Solid Clamp | 1" | 18" | 1500# |

Seals may be slected according to application requirements

Repair clamps Girder ring restraint split bolted closing

WA-SBC Girder split clamps are suitable for high temperatures applications with pipe operational pressures up to 3700 psi.

Split Repair Sleeves can be equipped with hinge plates and lifting eyes to simplify field installation.

Seals are firmly kept in place with steel girder rings.

Hydrostatic test certificates are supplied with each delivery.

Repair Clamps elbow design - high pressure units.

WA-BC bend repair clamps: are used to repair pipeline bends and elbows. Higher friction between the fluid and pipe wall normally occurs at pipe bends.

Elbows are identified by curve, angle or radius definition. Elbow repair clamps are used to repair may be used most pipe sizes with high or low operational pressures.

Split repair elbow clamp halves are closed by bolts to form a high integrity pressure seal around the damaged or leaking pipe section.

Elbow repair clamps may be installed without shutting down the pipe line. Elbow repair clamps of various angles may be repaired.

Sealing is provided by elastomeric seals selected for compatibility with the pipeline fluid and temperature.

Split repair clamps elbow design are manufactured to the outer dimension of the elbows, they offer the best solution for pipe angle repair.

Elbow leaks or weak or damaged elbow repair clamps are a solution for repairs at these vulnerable sections of the pipeline.

Elbow repair clamps are designed for ANSI Pressure classes 300-1500#. Design based on API 6H. Design calculation ASME Sec. VIII Div. I.

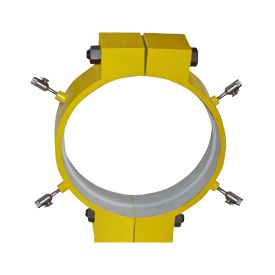

Flange Leak Repair Clamps - Stop leaks in flange gaskets

Flange leak repair clamps WA-FRC units are a permanent repair clamp for leaking flange gaskets under high operating pressure. The line remains in service during installation, no costly shutdowns.

No special flange surface preparation is required.

Flange repair clamps can be installed by company maintenance personnel.

There is no altering of existing flanges, other than cleaning the flange.

On scheduled shutdown maintenance the flange repair clamp can be removed and the gasket replaced. The unit may put back in service or held in stores for future repair.

Injection sockets are utilized to fully seal the compartment. In case of a small gap between the line flanges, gaskets can be installed for temporarily sealing prior too and during injection.

Product specification:

1. Body: ASTM A516 Gr.70

2. Stud Bolts: ASTM A193 Gr.. B7

3. Nuts: ASTM A194 Gr 2H

4. Gaskets: NBR

Design standards:

- API SPEC 6H, Specification on End Closures, Connectors and Swivels

- API SPEC 5L, Specification for Line Pipe

- ASME Pressure Vessel Code, Section VIII

- ASME/ANSI B18.2.1, Square and Hex Bolts and Screw Inch Series

Flange leak repair information sheet:

Download fill-in form for flange repair clamp: return form to Westatlantic Tech Corp.

Download flange leak repair cut sheet

High Pressure pipe - Line Tapping

WA-HPT: High Pressure pipeline tapping allows a drill cut to be placed in the line while the line is continues in service.

The Tap is designed to ASTM standards-B31.4, .8, 3 and ASTM B31.1.

ANSI class pipes 150#, 300#, 600# and 900# are available.

Contact Westatlantic Tech Corp., with your requirements.

Repair Clamps WA-RC-RH units have a corrosion resistant 316L Stainless Steel housing

Repair clamps WA-RH stainless steel units repair leaking pipes with operational pressures up to 16 bars - 235 psi.

Available with NBR and Viton seals. Fits all america and international pipe sizes.

Design standards:

- All metal parts: stainless steel AISI 304 or AISI316L.

- Double band (two sections) with a working range of 20-22 mm depending on the diameter.

- V gasket, steel reinforced to form the pressure chamber.

- Standard NBR rubber gaskets.

- Bridge plates are vulcanized into the rubber gasket.

- Bolts are PTFE (Teflon™) coated to prevent galling.

- No loose parts that may get lost during installation.

- No special tools required: a simple wrench will do the job.

- Under most circumstances the clamps can be installed. without releasing the pressure on the pipe.

The clamps can be used to repair the following pipe types:

- Ductile Iron (DI) - PE coated steel

- Cast Iron (CI) - PVC*

- Steel (St.) - GRP*

- Asbestos Cement (AC) - PE*

If pipe repair clamps are to be used on plastic pipes, please always contact Westatlantic for more information regarding the

application and restrictions on these pipe types.

Pipe Repair Clamps Stainless steel

Repair Clamps stainless body models WA-RS-1, WA-RS2, WA-RS-3, are used for permanent repairs of broken and damaged pipes

Application:

WA-RS-1 clamps are available in many different working ranges for pipes of DN 40 - DN 350.

WA-RS-1 clamps are available in many different working ranges for pipes of DN 40 - DN 350.

Available lengths: 150 / 200 / 250 / 300 / 400 / 500 / 600 mm.

WA-RS-2 clamps are available in many different working ranges for pipes of DN 80 - DN 800.

Available lengths: 200 / 250 / 300 / 400 / 500 / 600 mm

WA-RS-3 clamps are available in many different working ranges for pipes of DN 250 - DN 1000.

Available lengths: 300 / 400 / 500 / 600 mm.

Other lengths available on request. If you need to repair larger pipes 4 band or 5 band clamps are available depending on pipe OD.

Repair Clamps WA-HEAT model

Repair clamps HEAT models are used in tight spacers; for permanent repairs of broken and damaged pipes. Water, gas and petrochemical applications.

Application:

HEAT clamps are available in many different working ranges for pipes of DN 40 - DN 350.

Available lengths: 150 / 200 / 250 / 300 / 400 / 500 / 600 mm

Download brochure:

Repair clamps two band

High pressure stainless steel repair clamps can be used to repair leaking pipes up to 30 bars quickly and economically. Installation can be done by reqular maintenance with simple wrench tools. The products are easy to keep in stock and offer instant repair and quick savings. Available with NBR and Viton rubber.

All metal parts:stainless steel AISI 304 or AISI316L, passivated.

Double band (two sections) with a working range of 20-22 mm depending on the diameter.

V gasket, steel reinforced to form the pressure chamber

Standard NBR rubber gaskets

Bridge plates are vulcanized into the rubber gasket.

Bolts are PTFE (Teflon™) coated to prevent galling.

No loose parts that may get lost during installation.

No special tools required: a simple wrench will do the job.

Under most circumstances the clamps can be installed. without releasing the pressure on the pipe

Cut Sheet 2 band clamps

Pressure ratings and sizing in brochure

REPAIR CLAMPS 3 BANDS

WA-RS3

Pipe repair Clamps 3 Bands for permanent repairs of broken and damaged pipes in water, gas and petrochemical pipelines.

Application:

For pipes 10 inch up to 40 inch pipe (DN 250 - DN 1000).

Available lengths: 300 / 400 / 500 / 600 mm.

Other lengths on request. Larger than 40" pipe - 4 band or 5 band clamps are available.

Please contact Westatlantic for more information.

Download further details RS-2 Repair Clamps

Contact us: Westatlantic Tech Corp., 902 455 4455

Pipe repair clamps, split, bolted, bolted repair clamps, flange repair clamps, flange leak repair clamps. USA and Canada, USA: Texas, TX, Houston, New York, NY, Illinois, IL, North Dakota, ND, Iowa, IA, Ohio, OH, Michigan, New York, NY, Utah, Arkansas, Kentucky, KC, California, CA, Colorado, Denver, Louisiana, LA, Florida, FL., Pennsylvania, PA. Wisconsin, WI. Canada, Ontario, Oakville, Toronto, Mississauga. Alberta, AB; Edmonton, Calgary. British Colombia, BC; Vancouver, Saskatchewan, SK; Saskatoon, Manitoba MB; Winnipeg, Quebec, QC; Montreal,.